Blog

What is The Cost of Building a Prefab Home?

What is The Cost of Building a Prefab Home?

- What is the average cost per square foot to build a prefab home?

- Is it cheaper to build a prefab home or a traditional stick built home?

- What factors affect the cost of building a prefab home?

- How much does it cost to build a 1000 sq ft prefab home?

- What is included in the cost of a prefab home package?

- How can I get an accurate estimate for building a custom prefab home?

- What are the different types of prefab homes and how much do they cost?

- Can prefab homes be financed like traditional site-built homes?

- How do prefab home prices compare to manufactured or mobile homes?

- How can I reduce the cost of my prefab home?

What is the average cost per square foot to build a prefab home?

The cost per square foot to build a prefab home can vary quite a bit depending on the size and customization of the home. However, most industry experts estimate the average cost per square foot falls between $200-350.

Some of the factors that affect the cost per square foot of a prefab home include:

- Size of the home – Economies of scale come into play with prefab. The cost per square foot is generally lower for larger homes than smaller homes. This is because the fixed costs are spread over more square footage.

- Level of customization – More customized prefab homes cost more per square foot than standardized plans. Custom homes require more specialized engineering and materials.

- Building materials – Upgraded finishes like hardwood floors, high-end countertops and premium fixtures can increase the cost per square foot.

- Geo-specific requirements – Prefab homes destined for hurricane or earthquake prone areas require additional engineering and reinforced materials which increases costs.

- Foundation options – Typically concrete slab foundations are the most economical. Alternative foundations like piers or basement add more costs per square foot.

- Delivery method – craned modules vs shipped containers vs panelized kits – each method has different cost structures.

- Contractor rates – there are regional differences in labor and contractor rates.

So in summary, while the cost per square foot can range based on the above factors, most prefab homes fall between $200-350 per square foot. Going with standardized plans on an uncomplicated foundation helps reduce the price point.

Is it cheaper to build a prefab home or a traditional stick built home?

When it comes to cost, prefab homes tend to be 10-20% cheaper than comparable traditionally built homes. There are a few reasons why prefab homes have an advantage when it comes to construction costs:

- Factory efficiency – Prefab homes are built in a controlled factory setting optimized for efficiency. This allows for faster build times, less wasted materials, and lower labor costs.

- Economies of scale – Prefab factories producing multiple homes benefit from bulk purchasing of materials and streamlined processes. This reduces per unit costs.

- Less site work – Prefab homes require less extensive foundations and on-site construction work which saves significantly on labor and materials.

- Standardized designs – Following optimized floorplans and using stock materials keeps costs lower. Traditional custom homes require bespoke designs.

- Weather resistance – Building in a factory means no weather delays, fewer damaged materials and more consistent workflows – all factors that reduce costs.

- Shorter build times – Faster overall construction timelines mean lower financing costs for prefab homes. Slow-downs from weather or contracted labor have minimal impact on factory production.

However, prefab does have some additional costs to factor in such as transportation of the modules and heavy cranes needed for installation. Extra seismic or hurricane reinforcement may be required depending on the region.

In general though, the cost savings from factory efficiencies and standardization offset most of these additional expenses – making prefab 10-20% cheaper per square foot than comparable site-built construction.

What factors affect the cost of building a prefab home?

There are several key factors that impact the overall cost of building a prefab (prefabricated) home:

- Home size – Cost per square foot decreases as home size increases, due to economies of scale. Larger homes allow fixed costs to be distributed over more square footage.

- Customization – Prefab homes following standard plans are most cost effective. Highly customized homes require more specialized materials, design and labor.

- Building materials – Upgraded finishes like hardwood flooring, granite countertops or high-end fixtures will increase costs.

- Foundation – Typical concrete slab foundations are most economical. Basements, crawlspaces or piers add more costs.

- Delivery method – Whole building modules (craned into place) are generally cheaper than panelized or component systems.

- Transportation – Shipping distance from factory to site affects costs. Common strategies include local modular factories or hub-and-spoke models.

- Site accessibility – Tight urban lots or sloped terrain makes delivery/installation more complex and costly. Simple sites reduce crane rental and labor time.

- Regional requirements – Seismic or hurricane zones require additional structural reinforcement, adding costs. Areas with heavy snow loads need roof truss upgrades.

- Contractor rates – There are regional differences in labor and sub-contractor rates. Higher cost areas increase overall price.

- Factory capabilities – Some factories have greater customization abilities – but also charge higher premiums. Limiting custom touches containment costs.

So in summary, standard floor plans, smaller upgrades, simple foundations and accessible sites help reduce prefab home costs, while heavy customization, premium finishes and complex sites add to the overall price. Carefully balancing these factors allows for optimal cost-effectiveness.

How much does it cost to build a 1000 sq ft prefab home?

For a basic 1000 square foot prefab home, most industry experts estimate the cost falls between $150,000 and $300,000, with the average around $200,000.

The low end of the range represents a fairly standard modular home with minimal customization and basic finishes. The higher pricing reflects added features and upgrades like premium floors, countertops, fixtures and custom cabinetry.

A breakdown of estimated costs for a 1000 sq ft prefab home:

- Modular structure – This includes the shell, interior framing, windows, doors, roofing and siding. Range is $100 – $150 per sq ft, so $100,000 – $150,000 for a 1000 sq ft home.

- Transport – Average cost to deliver modules from factory to site is $10,000 – $20,000.

- Foundation – Simple concrete slab around $15,000. More complex foundations cost $25,000+.

- Site preparation – Grading, drainage, utilities hookups average $15,000 – $30,000.

- Crane costs – Typically $5,000 – $10,000. Higher for challenging sites.

- Interior fit-out – Basic finishes about $15,000. Upgraded floors, cabinets, fixtures $30,000+.

- Permitting fees – Varies by region but around $5,000 – $10,000 is typical.

Which puts a conservative range between $150,000 – $300,000 for a 1000 sq ft prefab home. Final cost depends on level of finishes, customization and foundation complexity. But the efficiencies of prefab make it very competitively priced versus traditional construction.

What is included in the cost of a prefab home package?

Prefab home packages typically include all the components needed to build a complete home, with a few key exceptions. Here’s an overview of what is usually included (and not included) in a basic prefab package:

Included in prefab package:

- Modular or panelized structural shell

- Exterior windows and doors

- Interior partition walls

- Cabinets and counter tops

- Interior doors, hardware and closet shelving

- Light fixtures and ceiling fans

- Most appliances like fridge, stove, dishwasher

- Plumbing and electrical rough-in

- HVAC ducting

- Insulation

- Drywall

- Exterior siding and roofing

Not included in prefab package:

- Foundation – priced separately

- Site preparation – priced separately

- Utility connections – priced separately

- Landscaping – priced separately

- Custom tilework or accent walls – upgrade costs

- Luxury fixtures, floors or finishes – upgrade costs

- Interior design services – upgrade costs

- Specialty add-ons like fireplaces – upgrade costs

So in summary, the base prefab home package contains most of the structural materials and standard finishes needed to build a complete home. But foundations, utility hookups, landscaping and customizations are typically priced separately, and added based on individual homeowner preferences. This allows buyers to customize the scope and budget of their prefab home.

How can I get an accurate estimate for building a custom prefab home?

Getting an accurate upfront estimate is crucial when budgeting for a custom prefab home. Here are some tips to get a precise quote:

- Provide detailed floor plans – Dimensioned layouts of each level allow prefab builders to price materials accurately and identify any design challenges.

- Specify all finishes – Provide specific models and grades for appliances, lighting fixtures, flooring types, cabinetry etc. Generic allowances leave room for error.

- Request itemized quote – Ask for an itemized quote rather than just a bottom line total so you can understand what is included.

- Outline electrical and plumbing – Mark locations for switches, outlets, fixtures, drains etc. This prevents missed items.

- Describe any custom features – Specify any unique windows, doors, tile accents, ceiling details that differ from standard spec.

- Factor in delivery route – Give the prefab builder your site address so they can assess any access challenges or road restrictions.

- Check foundation requirements – Your site soil type and slope determines the footing solution and costs.

- Understand taxation – Account for any sales taxes, building permit fees and development charges in your region.

- Get multiple quotes – Check pricing with 3-4 prefab builders to get a reliable cost range, not just one estimate.

- Confirm warranty coverage – Understand what defects or flaws are covered under the builder’s warranty.

Getting quotes early, with detailed plans and specifications, and checking pricing across multiple prefab builders helps ensure your custom home estimate is as accurate as possible.

What are the different types of prefab homes and how much do they cost?

There are several distinct types of prefab (prefabricated) home construction, each with their own cost factors.

Modular Homes

These are factory-built 3D home modules transported to site and craned into place. Modular homes have the following cost characteristics:

- $100-$200 per sq ft depending on finishes, customization

- Ideal for 1500+ sq ft homes when economies of scale kick in

- $15k-$30k for transport from factory to site

- $10k crane costs are common

Panelized Homes

Panelized homes are flat packed kits of walls, floors & roof panels assembled on site. Their costs include:

- $150-$250 per sq ft range driven by amount of finished panels

- Best for smaller homes under 1500 sq ft

- Lower shipping costs than modular, starting around $5k

- Minimal crane costs – assembled with small boom or jacking system

Tiny Homes

Tiny homes under 500 sq ft are a niche prefab category. Price factors are:

- $200-$300 per sq ft due to small size and specialty nature

- Built on trailer bed frame for mobility – $5k-$10k

- Lower shipping costs as they are compact and lightweight

Hybrid Homes

Hybrid systems combine panels and modules for cost and design flexibility:

- $150-$200 per sq ft range

- Often a mix of panels and modules

- Requires both trucking and crane but lower volumes of each

- Provides greater design flexibility

So in summary, prefab offers solutions at various price points but modular construction provides the best value for larger customizable homes.

Can prefab homes be financed like traditional site-built homes?

Yes, absolutely. Prefabricated (prefab) homes can be financed through all the same options available for conventional stick-built construction. This includes:

- Mortgages – Prefab homes are eligible for standard mortgages including conventional, FHA, VA, USDA and jumbo loans. Modular construction meets building codes and is considered lower risk lending.

- Construction Loans – Also called a builder line of credit, these provide financing throughout the building phase, converting to a mortgage upon completion.

- Personal Loans – Banks and online lenders offer personal loans that could be used to finance a prefab home. Often higher rates than mortgages however.

- Home Equity Loans – For homeowners with existing equity, a home equity loan or line of credit can provide funds to purchase a prefab home.

- Land Loans – If financing just the land initially, specialized land loans are available. The prefab home itself can then be financed separately.

When applying for financing, the same credit scores and debt-to-income rules apply as standard mortgages. The lender will also want:

- Signed prefab purchase agreement – Details total price, timeline, scope of included features

- Engineered designs – Factory blueprints stamped by structural engineer

- Warranty coverage – Most prefab companies provide a warranty up to 10 years

With these documents in place, prefab homes can be readily financed like any other home. The streamlined construction process and structural warranties also make prefab a lower risk option for both buyers and lenders.

How do prefab home prices compare to manufactured or mobile homes?

Prefab homes tend to be more expensive upfront than manufactured homes, but cheaper than mobile homes on a per square foot basis:

- Prefab homes – $200-$350 per sq ft

- Manufactured homes – $50-$100 per sq ft

- Mobile homes – $100-$150 per sq ft

There are some key differences that account for the pricing variance:

Prefab Homes

- Custom designed using modular components

- Assembled on site from modules

- Adhere to local building codes

- Designed for permanence

- Appreciate in value

Manufactured Homes

- Factory built to federal HUD code

- Delivered whole via truck

- Limited customization

- Depreciate over time

Mobile Homes

- Pre-owned units

- Satisfy HUD codes previously

- Transported intact to sites

- Depreciate over time

- Lower cost than new manufactured

In summary, prefab homes require greater upfront investment but also increase in long-term value more than manufactured or mobile homes. The customization and quality finishings of prefab command the cost premium.

For buyers focused purely on affordability, manufactured homes provide new construction at the lowest price point. But prefab offers a middle ground – higher quality than manufactured at competitive per square foot pricing.

How can I reduce the cost of my prefab home?

Prefabricated homes provide inherent cost efficiencies, but there are still ways to further reduce your total prefab spend:

- Choose a standard floorplan rather than extensive customization

- Opt for stock materials and finishes – avoid expensive upgrades

- Go for a smaller overall home size – costs per sq ft drop for larger builds

- Pick a simple rectangular layout – complex shapes add engineering costs

- Install on a concrete slab foundation – eliminates need for basement or crawlspace excavation

- Select a single story – multi-story add more structure, stairs and roofing

- Ensure the site has easy access – avoids crane issues and site prep complexity

- Keep plumbing and electrical simple – each bend, connection and fixture adds labor and supplies

- Choose energy efficient HVAC and appliances – reduced lifetime operating costs

- Shop multiple prefab builders – compare pricing and financing terms

- Pay upfront rather than finance – avoids interest charges and fees

- Act as own general contractor – reduces middleman markup if DIY savvy

Making structural and layout choices that maximize standardization and simplify installations is key to controlling prefab costs. Comparing bids and minimizing financing costs also keeps overall spend lower.

Key Takeaways

Some key takeaways about the cost of building a prefab home:

- Cost per sq ft ranges from $200-350 for most prefab homes

- Prefab is 10-20% cheaper than comparable traditional construction

- Customization, complex foundations and premium finishes increase costs

- Basic 1000 sq ft prefab averages $200,000 in total price

- Modular construction provides most economies of scale for larger builds

- Prebabs can be financed through same mortgages, loans as site-built homes

- Upfront cost higher than manufactured homes but long-term value appreciation greater

- Standardization, simplification and DIY help reduce prefab costs

So although not the absolute cheapest construction method, prefab offers quality and customization at very competitive per square foot pricing.

Conclusion

Overall, prefabricated homes offer a cost-effective way to build a high quality, customized home. While not the absolute lowest cost option, prefab pricing is very competitive at $200-350 per square foot – 10-20% cheaper than comparable site-built construction.

The key factors that influence prefab costs include the level of customization, building materials and finishes, foundation type, delivery method, and additional regional requirements. Basic prefab homes with standardized plans on simple slab foundations provide the most affordable options. More complex designs, premium finishes and challenging site conditions add to the pricing.

When it comes to alternatives, manufactured homes have lower upfront costs at $50-100/sq ft but also lower long-term value. Mobile homes offer used units at a discount. For quality and customization, prefab provides a solid middle ground.

With good planning, design choices and comparison shopping, buyers can optimize the cost-effectiveness of a prefab home while still getting modern architectural design highly tailored to their needs. Prefab makes customized, energy efficient, durable homeownership attainable at competitive rates compared to conventional building.

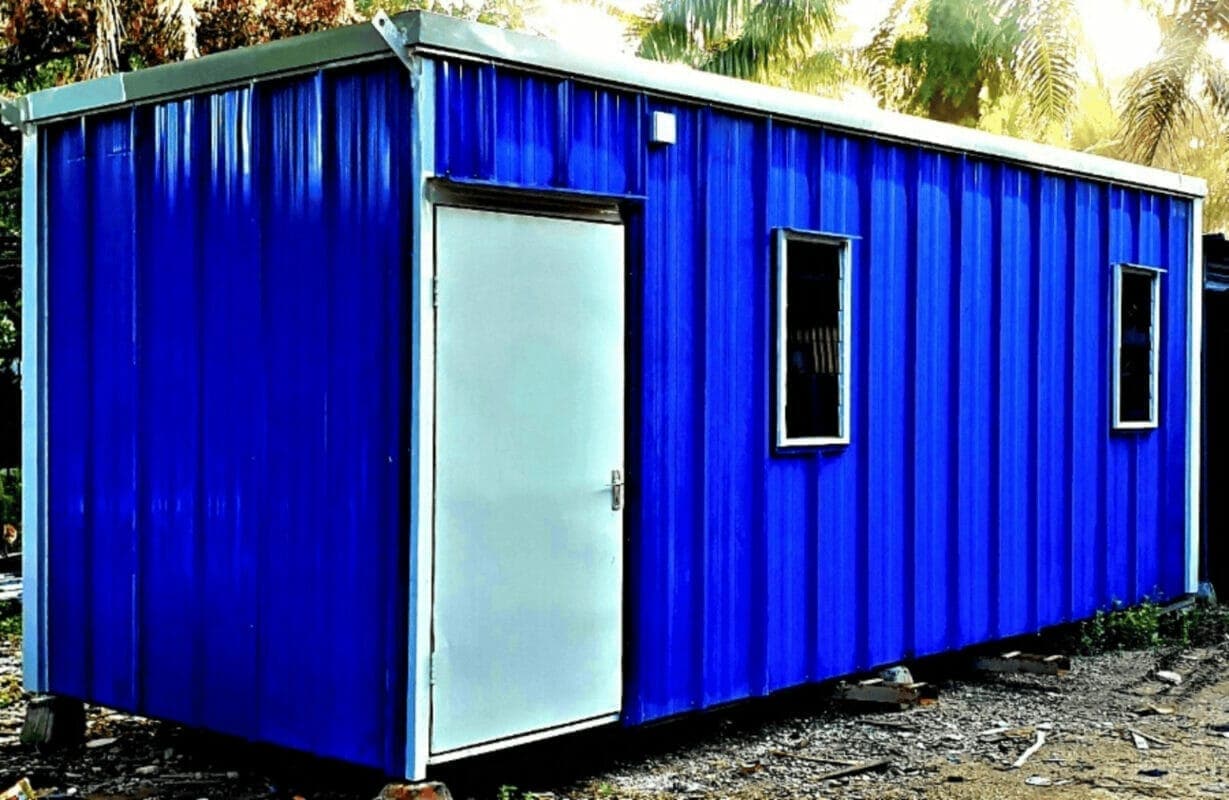

Kontraktor Rumah Kabin

Rumah Kabin Murah

Rumah Kontena Vs Rumah Kabin

Rumah Kabin Pasang Siap

Senarai Harga Kabin di Malaysia

Heavy Duty Cabin

Light Duty Cabin