Blog

Pros and Cons of Prefab Homes in Malaysia

Pros and Cons of Prefab Homes in Malaysia

- What are the main advantages of prefab homes compared to traditional construction in Malaysia?

- How much cheaper are prefab homes compared to traditional homes in Malaysia?

- What are the downsides or disadvantages of prefab homes in Malaysia?

- How customizable are prefab homes – can I make changes to the floorplan and layout?

- How long does it take to build a prefab home in Malaysia compared to traditional construction?

- Are prefab homes in Malaysia of lower quality or do they last as long?

- What options are there for exterior finishes and styles for prefab homes in Malaysia?

- Can I get a prefab home on my own land or do I need to buy in a prefab community?

- What are the limitations for prefab homes in Malaysia in terms of size, stories, layout?

- How are prefab homes transported and assembled on site in Malaysia?

What are the main advantages of prefab homes compared to traditional construction in Malaysia?

Prefab homes, also known as prefabricated or modular homes, have become an increasingly popular housing option in Malaysia in recent years. There are several key advantages that prefab homes offer compared to traditional stick-built construction:

- Faster construction time – This is one of the biggest benefits of prefab homes. Since up to 80% of the home is manufactured in a factory, construction can be completed much more quickly, often in as little as 3-5 months. This compares to 12 months or longer for traditional construction.

- Lower costs – Prefab manufacturing allows for more efficient use of materials and streamlined processes, reducing wasted time and materials. This makes prefab homes up to 20% cheaper than conventional homes in Malaysia.

- Quality construction – Prefab homes are constructed in a controlled factory setting using precision equipment, allowing for higher standards of quality control. Materials can also be protected from weather during construction.

- Customization – There is flexibility to customize floor plans, facades, interiors within certain parameters. Homeowners have options to select layouts, materials, fixtures, finishes.

- Eco-friendly – Prefab homes require less energy to construct and allow for sustainable materials and green technology integration more easily. Waste is reduced compared to on-site construction.

- Minimal disruption – With prefab, the majority of construction happens off-site in a factory, minimizing noise, dust and disruption on the final building site. This allows owners to continue using existing home during the process.

- Resilient structure -Prefab components are assembled on rigid frames providing superior structural integrity and ability to withstand natural disasters like earthquakes.

On the whole, prefab homes in Malaysia allow for faster, cheaper, lower waste housing with quality and customization advantages compared to traditional building. As more prefab builders emerge in Malaysia, the benefits continue to drive consumer interest and growth.

How much cheaper are prefab homes compared to traditional homes in Malaysia?

Prefab homes in Malaysia provide a more affordable housing option, with total costs typically 15-20% lower than comparable traditionally built houses. Here is an overview of the cost differences:

- Land acquisition – This cost is essentially identical for prefab vs traditional homes. Land costs in Malaysia vary widely based on location.

- Construction costs – This is where major savings of 15-20% can be achieved with prefab. Factory construction techniques, materials buying in bulk, and reducing waste allows prefab home builders to reduce overall build expenses.

- Material costs – Prefab allows material costs to be optimized by precise engineering and no waste. Higher quality materials can also be sourced more affordably. Overall prefab material costs are 10-15% less.

- Labor costs – Labor makes up 15-20% of traditional home costs. Prefab reduces on-site labor significantly, with most construction done in the factory. Overall 50-70% savings in labor.

- Time costs – Shorter construction timelines mean lower financing costs and savings on rent/temporary housing. Prefab homes can be completed in 3-5 months instead of over 12 months.

- Logistics costs – Transporting prefabricated modules has specialized requirements. However, optimized routing, bundles and experienced firms reduce this cost. Overall prefab logistics add only 2-4% to costs.

In summary, while there is some variation based on house size, location and builder, prefab homes in Malaysia provide an average total cost savings of 15-20%, or over RM50,000-RM100,000 for most buyers.

What are the downsides or disadvantages of prefab homes in Malaysia?

While prefab (prefabricated) homes have many benefits, there are also some potential downsides to consider:

- Limited customization – Prefab homes allow for some degree of customization to layout, materials, finishes. However, there is less flexibility compared to building a fully custom stick-built house.

- Smaller lot options – Prefab homes work best on flat plots that can accommodate deliveries. So they may not be suitable for very small, oddly-shaped or steep lots.

- No basements – The modular construction process makes basements unfeasible for most prefab homes. Above ground options only.

- Multi-story limits – Most prefab homes are single story. Building multiple floors requires special design and engineering.

- Resale value uncertainty – Prefab homes are still establishing their resale value in Malaysia. There is some perception risk vs traditional homes.

- Not for unique designs – Homes with unusual shapes, arches etc are difficult to create with prefab. Best for simple or minimalist aesthetic.

- Site preparation still required – Land must be prepared with foundations and utilities ready before module delivery.

- Transport access – Routes to the site must be clear for trucks to deliver home modules, which may add complications.

- Future expansion limitations – Adding on to certain areas of a prefab may be constrained or require full reconstruction.

While prefab has downsides, most can be anticipated and managed through careful planning, lot selection, builder discussion and design choices. Overall prefab homes remain a smart option for many Malaysian homebuyers.

How customizable are prefab homes – can I make changes to the floorplan and layout?

One major benefit of prefab (prefabricated) homes is they still allow for a reasonable degree of customization, unlike manufactured mobile homes. Here are some of the layout and floor plan changes that can be made:

- Select overall dimensions – Most prefab builders offer a choice of widths and number of modules to determine overall square footage. Common widths are 20ft, 24ft, 28ft.

- Choose from model floor plans – Builders will have a number of model home floor plans to select from as a starting point. These can then be modified.

- Revise interior walls – The interior wall layout can usually be adapted by moving or removing non-load-bearing walls. However structural changes may be limited.

- Combine open concept spaces – Modules can be joined into more open concept great rooms by removing dividing walls. However plumbing locations may limit changes.

- Modify windows and doors – Window and exterior door locations and sizes can typically be changed with relative flexibility.

- Add interior doors – Interior door locations are also very changeable to alter room connectivity as needed.

- Shift interior fixtures – The locations of fixtures like sinks, toilets, bathtubs can usually be adjusted, albeit within certain plumbing limitations.

- Pick finishes/materials – Homeowners can select different cabinetry, countertops, flooring types, colors and finishes within the prefab builder’s options.

So while not infinitely flexible, prefab homes offer ample options for personalizing layouts and finishes to suit buyer preferences. Experienced prefab builders will work closely with clients to adapt designs while maintaining structural integrity.

How long does it take to build a prefab home in Malaysia compared to traditional construction?

One major advantage of prefabricated homes versus standard construction is the accelerated timeline. Here is an overview of how prefab home construction timelines compare:

- Prefab home timeline – For a typical single story prefab home, construction takes 3-5 months from start to finish. The timeline includes:

- 1 month for site preparation

- 1-2 months for module construction offsite

- 1-2 months for module delivery, assembly on site

- Traditional home timeline – Building a comparable traditionally constructed house takes 12-18 months, including:

- 2-3 months for site preparation

- 8-12 months wood frame construction on site

- 1-2 months M&E finishing

- Over 2x faster – Due to the ability to have site preparation and module construction happening simultaneously, prefab homes can be built more than twice as fast as conventional construction.

- Reduce temporary housing – The accelerated prefab timeline means buyers can move into their permanent new home after 5 months rather than staying in temporary accommodation for over 12 months waiting for traditional construction.

- Earlier return on investment – The ability to complete the build faster allows owners to move in and begin realizing returns sooner when the home is rented out or flipped.

So for buyers who need a new home built quickly or want to minimize transitional housing, prefab homes in Malaysia offer construction timelines of just 3-5 months from start to finish. This faster turnaround is a major benefit compared to typical construction.

Are prefab homes in Malaysia of lower quality or do they last as long?

There is a common misperception that prefabricated homes may be lower quality than site-built houses, but prefab construction actually allows for many quality advantages:

- Precise factory construction – Manufacturing in a controlled setting allows for greater precision cutting, assembly, finishing for tight construction tolerances.

- Quality materials – Suppliers provide consistent, high-grade materials that are protected from weathering during the prefab process.

- Skilled technical labor – Factory workers are specialists in home construction, unlike transient site contractors. Their expertise improves quality.

- Rigorous QC protocols – Stringent quality control at each step from design, materials checks, production workflow and final inspections.

- Certified structural integrity – Prefab modules are engineered to strict building codes and withstand transportation before final assembly.

- Multi-step finishing – Prefab interiors are finished in the factory with prime painting, cabinets, tiling etc before final touches on site.

- Built to last – Prefab manufacturers back their build quality with 50+ year structural warranties similar to traditional homes.

- Proven resilience – There are many examples of prefab homes surviving major quakes, storms and fires better than site-built homes.

While production techniques differ, prefabricated homes match or exceed the quality, durability and longevity of traditional construction, making them a smart housing choice for Malaysian families.

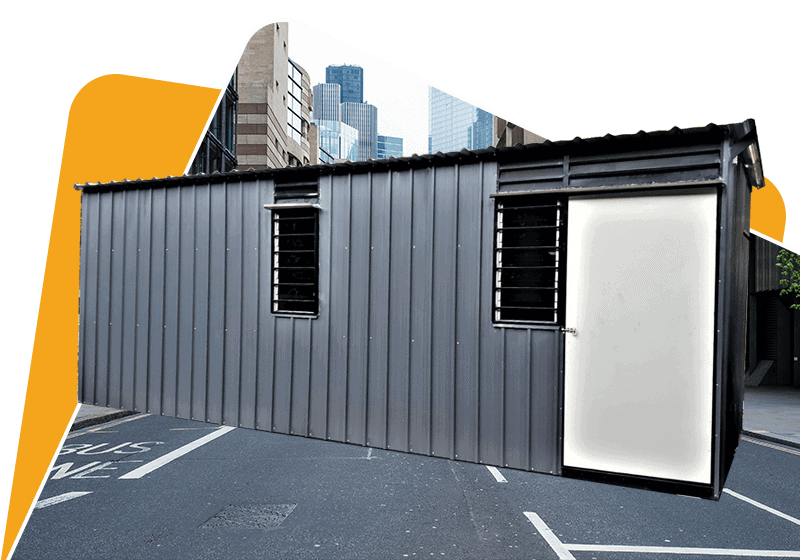

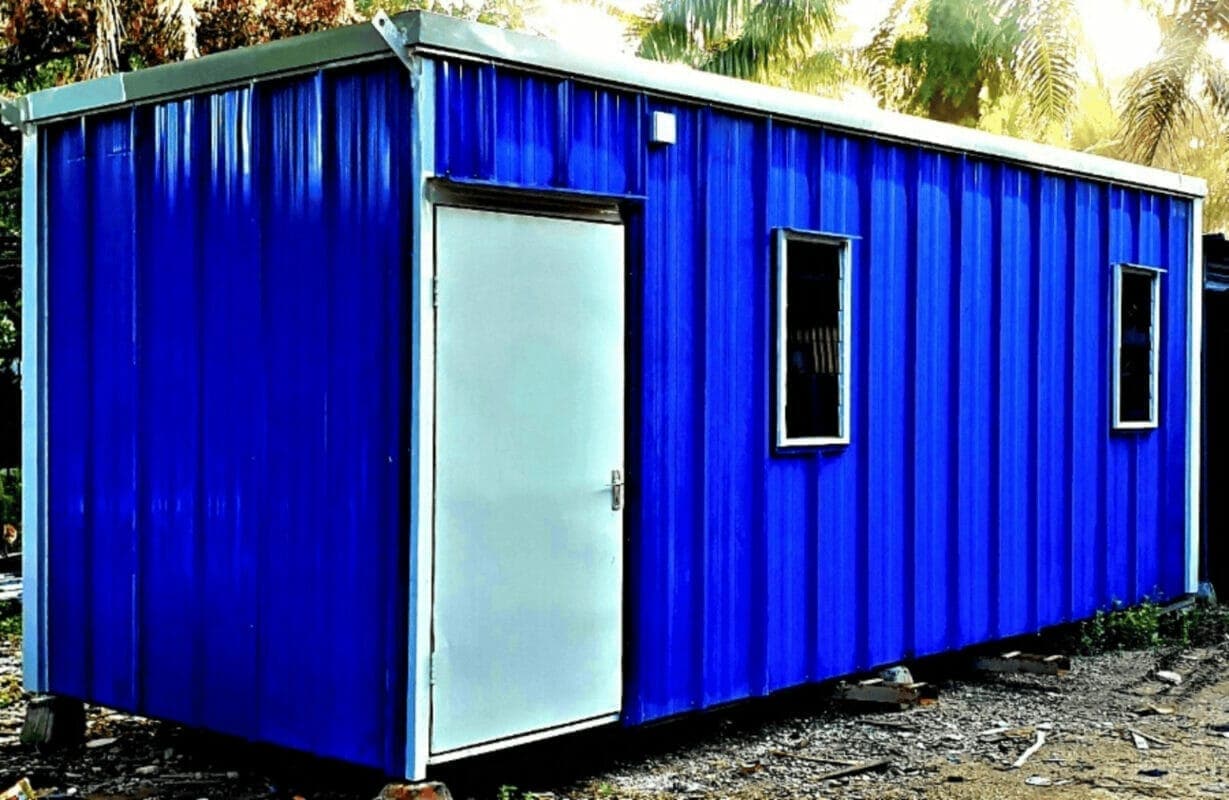

What options are there for exterior finishes and styles for prefab homes in Malaysia?

Prefabricated homes offer ample options for customized external finishes and architectural styles:

- Facade materials – Can select various standard or premium materials: brick, stone, stucco, cement board, aluminum siding, timber.

- Roof styles – Choose from gable, hip, barn, flat roof designs with desired roofing material – tile, metal, asphalt shingle.

- Colors/textures – Many colors and textured finishes like wood grain are available for exterior walls and trim.

- Architectural styling – Options range from traditional pitched roof to contemporary flat roof to rustic country to modern tropical designs.

- Windows – Choose layout, number, sizes and styles of windows like bay, casement, awning. Can add special shapes.

- Entry doors – Select material (wood, fiberglass), style, accent colors for front and rear entry doors. Add glass sidelights or transom windows.

- Garages – Choose attached or detached garage with desired door styles.

- Porches – Add partial- or full-width front porches with gable or hip roof and pillars.

- Landscaping – Fully customize site grading, plants, trees, gardens, patios around the prefab home.

With flexibility in materials, colors, roof designs, architectural elements and landscaping, prefab homes can be completely customized to match any desired exterior style.

Can I get a prefab home on my own land or do I need to buy in a prefab community?

A major benefit of prefabricated homes is you have flexibility with the lot or land options:

- Custom land – Prefab homes can be built on any privately owned residential land with appropriate zoning that the buyer provides.

- Prefab community – Some prefab builders develop communities where you purchase a completed home and leased land from them.

- Size – Land should be sized appropriately for home footprint plus buffer space for site access. Typical minimums are 18ft x 100ft for narrow homes.

- Dimensions – The shape of land shouldn’t be too irregular. Wide frontage for road access is best. Some slope is fine.

- Access – Land must have driveway access for semi-trailer trucks to deliver home modules. Overhead obstructions should be avoided.

- Foundations – Land for prefab requires poured concrete slab or concrete footings designed to mate with home.

- Utilities – Prefab homes require standard residential utility connections – power, water, septic/sewage, gas if needed.

- Permitting – Most local councils allow prefab on private land with standard residential permits. Zoning should be checked.

With proper planning for access, foundations and utilities, prefab homes give flexibility to build on existing private land or buy into prefab community lots.

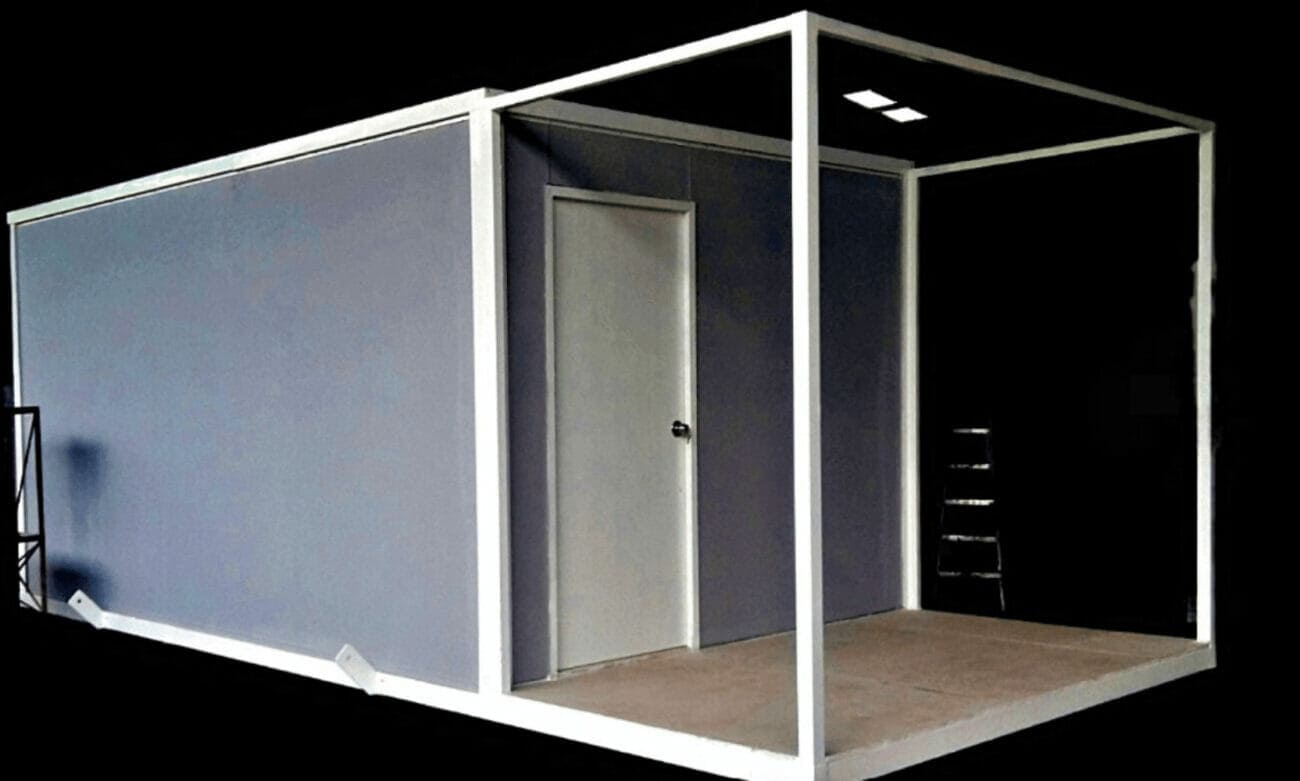

What are the limitations for prefab homes in Malaysia in terms of size, stories, layout?

Prefabricated homes offer flexibility in size and layout but do have some constraints compared to conventional construction:

Size

- Smaller single-module homes range from 550 – 950 sq ft.

- Mid-size with 2-3 modules are 1200 – 2500 sq ft.

- Largest designs can reach 3000+ sq ft but require special transport.

Stories

- Most prefab homes in Malaysia are single story.

- Double story prefab homes require complex engineering and factory capabilities. Stairs are typically not prefabricated.

Layout

- Simple perimeter or split layouts work best to optimize modular design.

- Minimize large open spans which are hard to support with modules.

- Consider plumbing runs crossing between modules in the floorplan.

Rooms

- Bedrooms and bathrooms are easy.

- Large open concept kitchen-living areas may need divides.

- High load rooms like laundry need special reinforcements.

Roof

- Gable and hip roofs are most feasible. Limited roof overhang sizes.

- Dormers, valleys, turrets are difficult with modular roofs.

Overall prefab homes work best when floorplans are optimized for modular construction during the design process. While not able to match the unlimited flexibility of site-built, prefab can accommodate most buyer needs.

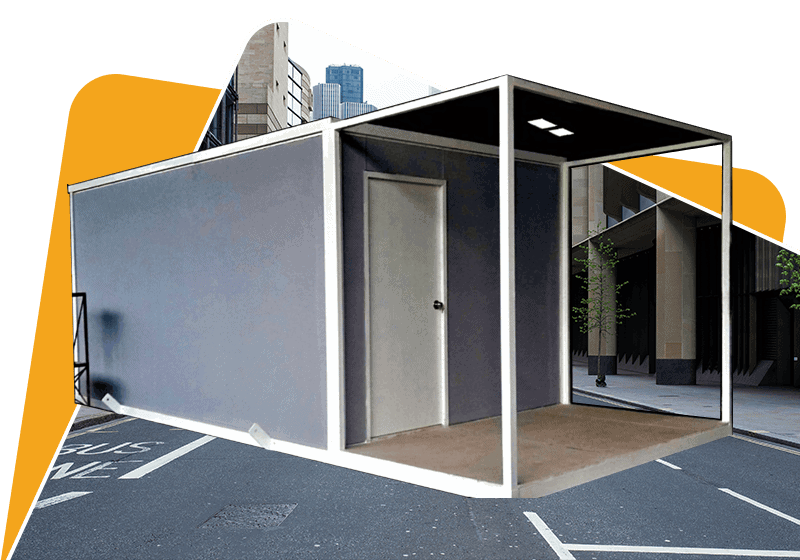

How are prefab homes transported and assembled on site in Malaysia?

Prefabricated homes require specialized logistics and installation on site once factory construction is complete:

- Transport – Completed modules are loaded onto licensed heavy haul trucks for road transport. Typical trucks can carry 1-2 modules per load depending on size.

- Routes – Transportation routing is planned in advance. Routes must accommodate load dimensions, turning radii, overhead clearance, road strength. Police escorts help.

- Cranes – On site, large cranes are used to lift and place modules from the trucks onto the home’s foundation. Crane capacities range from 30-120 tons commonly.

- Assembly – Modules are aligned precisely on the foundations using laser levels and surveying equipment to connect structures seamlessly. Gaps are under 10mm typically.

- Linking – Once set, modules are physically linked using site built structural connections that tie flooring, walls and roofing securely together into one integrated home.

- Utilities – Plumbing, electrical, HVAC components are linked between modules on site and connected to main utilities. State of the art sealing ensures joints stay protected.

- Finishing – Final finishes like tiling, painting, trim work and fixtures are installed on site after assembly to complete the home construction.

With good planning and experienced crews, the transport and on-site assembly process allows prefab homes to come together smoothly as turnkey modern residences.

Key Takeaways on Prefab Homes in Malaysia

- Prefab homes can be 15-20% cheaper than traditional construction, offering major cost savings.

- Construction timelines are 2-3x faster for prefab, taking only 3-5 months total.

- Customization of layout, finishes and facades is possible within modular constraints.

- Quality of prefab homes rivals or exceeds standard building with tight precision, materials and processes.

- Homes can be built on bought private land or leased land in prefab communities.

- Limits exist on size, stories, roof lines but most buyer needs can be accommodated.

- Specialized transport and cranes are used to deliver and assemble modules on foundations.

Overall, prefab homes present an appealing modern housing option for Malaysian families looking to build affordable, quality homes faster.

Conclusion

Prefabricated homes are shaking up the real estate landscape in Malaysia by offering faster, cheaper housing options without sacrificing quality or customization. With benefits like controlled factory construction, optimized materials usage and accelerated timelines, prefab homes can be built in as little as 3-5 months at around 15-20% lower cost versus typical 1-2 year construction projects. Though some constraints exist around design like multi-story limits, prefab builders work closely with clients to deliver turnkey contemporary homes adapted to local aesthetics on bought or leased land. With the advantages in affordability, construction speed and sustainability, prefab has become an increasingly attractive option for Malaysian homeowners and investors seeking modern, quality residences that meet their budget and lifestyle needs. The emergence of prefab as a viable alternative is set to continue growing and push construction innovation in the country.

Kontraktor Rumah Kabin

Rumah Kabin Murah

Rumah Kontena Vs Rumah Kabin

Rumah Kabin Pasang Siap

Senarai Harga Kabin di Malaysia

Heavy Duty Cabin

Light Duty Cabin