Blog

10 Popular Questions About Light Duty Cabin

10 Popular Questions About Light Duty Cabin

- What are the key features and benefits of a light duty cabin?

- What size light duty cabin do I need for my truck?

- How do I choose the right light duty cabin for my needs?

- What are the different materials used to construct light duty cabins?

- How much does a light duty cabin cost?

- Can I customize or modify a standard light duty cabin?

- How difficult is it to install a light duty cabin on my truck?

- What kind of warranty and support does the manufacturer provide?

- How do light duty cabins compare to fiberglass caps and camper shells?

- Are light duty cabins safe and secure for hauling equipment and tools?

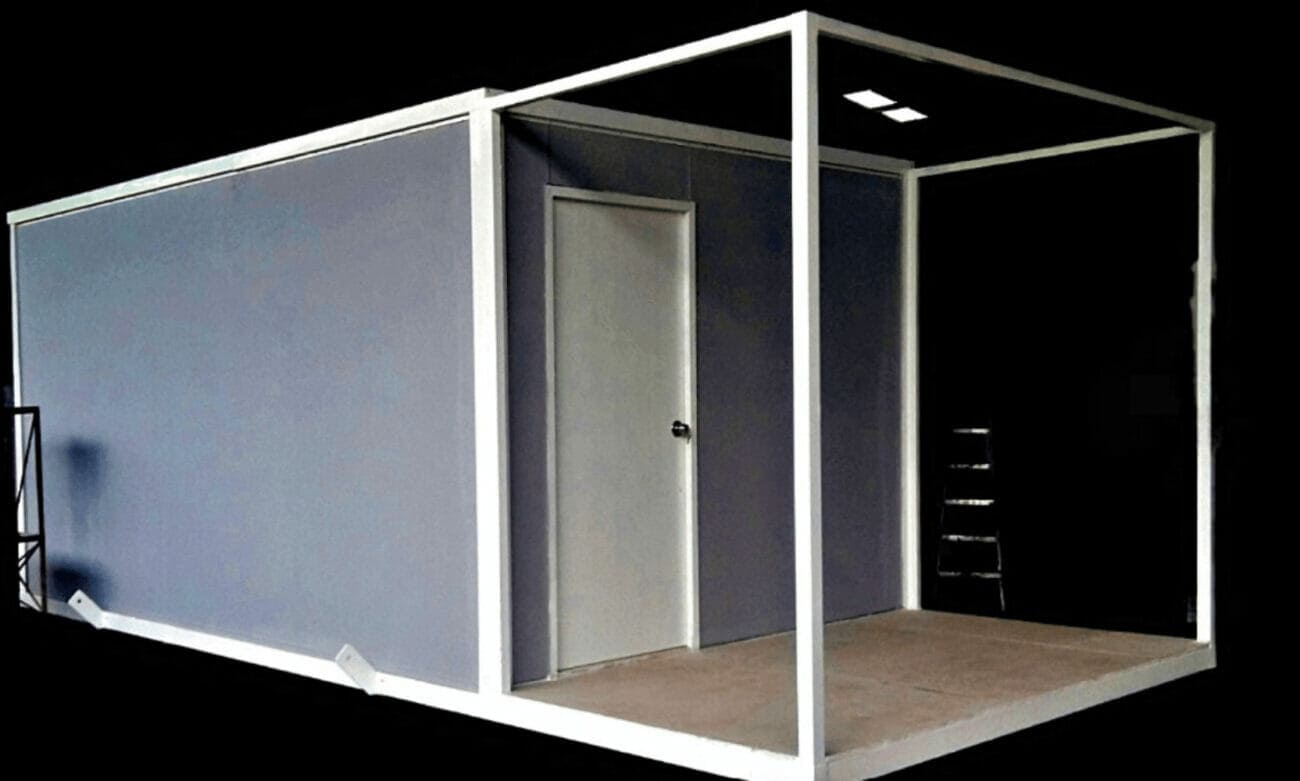

1. What are the key features and benefits of a light duty cabin?

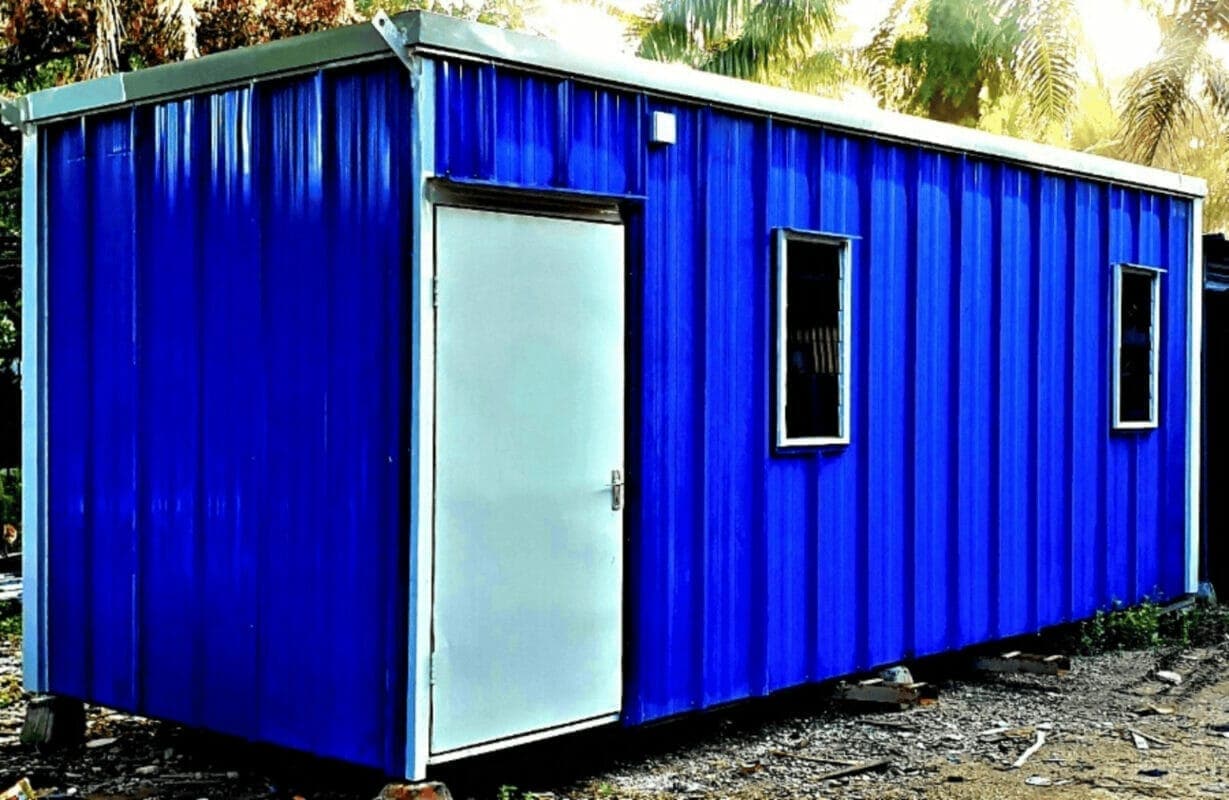

A light duty cabin is a great way to expand the functionality and versatility of your pickup truck. Here are some of the key features and benefits of adding a light duty cabin:

- Expanded cargo capacity – Light duty cabins provide you with a large, lockable, and weatherproof space for hauling equipment, tools, and other cargo. The enclosed space is much bigger than what you get with a truck bed cover.

- Customizable storage – Many light duty cabins allow you to customize the interior storage with shelving units, drawers, racks, and other accessories. You can optimize the space for your specific cargo needs.

- Protection from weather – The cabin enclosure protects your cargo from rain, snow, wind, and other elements that can damage equipment. The secure, lockable doors also deter theft of your cargo.

- Improved fuel economy – The aerodynamic design of most light duty cabins reduces drag and turbulence at highway speeds, which can improve your fuel efficiency compared to an open bed. Estimates range from 10-20% improvement.

- Flexible access – Light duty cabins have large doors or lift gates to allow easy access to your cargo from the sides or rear. The multiple access points make it convenient to load and unload.

- Better organization – The enclosed space allows you to secure cargo and separate dirty or messy items from the rest of your gear. The cabin keeps all your equipment neatly contained.

- Expanded seating – Some light duty cabins offer bench seating with seat belts and restraints. This allows you to carry additional passengers safely.

- Rugged durability – Light duty cabins are built tough to handle heavy use and abuse. The exterior is dent, rust, and corrosion resistant to maintain its appearance and function.

2. What size light duty cabin do I need for my truck?

Choosing the right sized light duty cabin for your truck depends on a few key factors:

- Truck bed length – Make sure to get a cabin that matches your truck bed length. Standard bed sizes are 6.5 ft, 8 ft, and 9 ft. Measure the bed length and account for the tailgate.

- Type of cargo – Consider the size, shape, and weight of the items you’ll be hauling. Bulky or oversized cargo will require more space. You’ll also need more capacity for heavier loads.

- Future needs – Get a cabin that provides some extra room to allow for future cargo growth or changes in your hauling requirements. Don’t size it just for your immediate needs.

- Truck payload capacity – The GVWR and payload capacity of your truck determines the maximum weight you can safely haul. Make sure to get a cabin weight that does not exceed your payload when loaded.

- Truck cab style – Extended cab and crew cab trucks have shorter beds. Make sure to get a proportionally shorter cabin for the best fit.

Here are some typical light duty cabin lengths to consider:

- 6.5 ft truck bed = 60-72 inch cabin

- 8 ft truck bed = 84-108 inch cabin

- 9 ft truck bed = 108-120 inch cabin

Measure your exact bed length and account for wheel wells and tailgate clearance when choosing the cabin size. Allow for future cargo growth too.

3. How do I choose the right light duty cabin for my needs?

Here are some tips for choosing the best light duty cabin to suit your hauling needs:

- Assess your cargo – Make a list of the types of equipment, tools, and materials you need to haul on a regular basis. This will help determine the necessary storage space and options.

- Consider weight capacity – Check the cabin’s weight rating and ensure it falls within your truck’s payload capacity when fully loaded. Heavier duty models are available.

- Choose accessible doors – Look for side and rear door configurations that will make accessing your cargo convenient. Lift gates are great for heavy items.

- Evaluate durability – Examine the cabin’s structural integrity and impact, corrosion, and weather resistance for your working conditions. Opt for robust materials.

- Compare security features – Look for sturdy door locks, window coverings, and mounting systems to keep your cargo secure. Alarms can provide additional protection.

- Assess custom options – Many manufacturers offer interior customizations like shelving, drawers, and racks to organize your cargo. Get the options you need.

- Check the warranty – Opt for a long warranty (5-10 years) to protect against leaks, equipment failure, corrosion, etc. Longer coverage provides more peace of mind.

- Read reviews – Check reviews and talk to other owners to learn about real-world performance, fit, ease of use, and service issues for different cabins.

- Get the right fit – Confirm the cabin length fits your truck bed properly. Measure wheel wells and account for tailgate clearance.

4. What are the different materials used to construct light duty cabins?

Light duty cabins are commonly constructed from aluminum, steel, or fiberglass. Here is a comparison of the most common cabin building materials:

- Aluminum – Lightweight, corrosion-resistant, and very durable. Aluminum cabins are popular for their strength, security, and longevity. More expensive than steel.

- Steel – Very strong and impact resistant, but susceptible to rust if not properly treated. Coated steel cabins offer good value and security. Heavier than aluminum.

- Fiberglass – Light, rustproof composite material. Not as impact resistant as metal but requires less maintenance. Provides good insulation.

- Wood – Traditional material that requires heavy maintenance. Vulnerable to moisture damage over time. Rarely used in modern cabins.

- Hybrid – Some manufacturers use a hybrid mix of materials. For example, aluminum exterior with high-strength steel framing. This combines the durability and weather-resistance of aluminum with added structural integrity.

Here are some pros and cons of common cabin building materials:

Aluminum

Pros:

- Lightweight

- Corrosion resistant

- High strength-to-weight ratio

- Long lifespan

Cons:

- Expensive

- Can dent easily

- High thermal conductivity

Steel

Pros:

- Very strong and impact resistant

- Can be made very secure

- Lower cost than aluminum

Cons:

- Heavy

- Susceptible to rust without treatment

- Can transfer more heat/cold

Fiberglass

Pros:

- Lightweight

- Highly weather and corrosion proof

- Good noise and temperature insulation

Cons:

- Not as strong or secure as metal

- Can crack on impact

- Needs gelcoat maintenance

So in summary, aluminum and steel are the most common and versatile light duty cabin materials, while fiberglass is lighter but less robust. The right material depends on your specific needs and budget.

5. How much does a light duty cabin cost?

The cost of a light duty cabin can vary quite a bit depending on the size, features, materials, and manufacturer. Here is an overview of typical light duty cabin pricing:

- Basic Steel Cabin – $1,500 – $3,000

- Entry-level coated steel cabin with limited options. Basic security and storage functionality.

- Mid-Range Aluminum Cabin – $3,000 – $7,000

- Medium-duty aluminum construction with more custom options. Better durability and security than basic steel.

- Premium Aluminum Cabin – $7,000 – $15,000

- Heavy-duty aluminum with maximum security and storage customizations. Top-end models with lift gates.

- Fiberglass Cabins – $2,000 – $6,000

- Typically smaller and lighter. Not as heavy-duty as aluminum or steel. Good for fuel economy.

Additional costs may include:

- Custom paint or wraps – $500-$2,000

- Additional access doors – $300-$1,000

- Interior shelving and storage packages – $500-$2,000

- Remote security and alarm systems – $750-$2,000

- Power lift gates – $1,500-$3,000

- Extended warranty coverage – $400-$1,000

Shop around and compare warranties, construction quality, security, and custom options when choosing a light duty cabin in your budget. Consider the long-term durability and functionality you need.

6. Can I customize or modify a standard light duty cabin?

Yes, many light duty cabins allow for some degree of customization or aftermarket modifications to adapt them to your specific cargo needs:

- Interior shelving – Most manufacturers offer interior shelving packages or you can install your own shelving using tracks or brackets. Optimize the space for your tools or cargo.

- Drawers and storage boxes – Add lockable drawers or storage containers to keep smaller items organized and secure. Useful for storing valuables or work tools.

- Racks and mounts – Install racks, hooks, and mounting brackets for securing odd-shaped items or safely transporting long/dirty cargo like ladders, pipes, lumber etc.

- Interior lighting – Install interior LED light strips or spot lights to illuminate the interior when loading at night or in low-light conditions.

- Access doors – Some models allow you to add or reconfigure side/rear doors to improve access such as adding a lift gate.

- Power systems – You can integrate electrical systems for powering interior lights, charging tools, running a winch, or temperature control. Requires wiring expertise.

- Windows – Install windows or portholes to increase interior light and visibility. Just ensure they are secure and lockable.

- Weight rating – Reinforce the floor and structure if you want to increase the cabin’s maximum weight capacity for heavier loads.

Always check with the manufacturer before making major modifications to ensure you do not void the warranty. Some customization options may also require professional installation for safety.

7. How difficult is it to install a light duty cabin on my truck?

Installing a light duty cabin on your truck is a project you can usually tackle yourself with some mechanical skills and help from a few friends. Here is an overview of the installation process:

- Pickup bed prep – Remove any existing bed liner and thoroughly clean/prep the bed area. This ensures proper cabin fit.

- Positioning – Hoist the cabin onto the bed using lifting equipment. Carefully position it centered and squared on the bed.

- Mounting – Bolt the cabin securely to the truck bed using the provided mounting hardware kit. Most models use a bolt-on bracket system.

- Securing – Add any additional reinforced metal plates, angle brackets, or straps to properly secure it and prevent shifting during transport.

- Door clearance – Confirm all doors open/close freely without rubbing against the bed sides or tailgate. Adjust position if needed.

- Electrical – Hook up any wiring like lights or alarms to your truck’s electrical system. Use good waterproof connections.

- Weatherproofing – Seal any gaps with caulk and add weatherstripping around doors to prevent water intrusion.

- Finishing touches – Install any interior accessories like shelving. Add a quality bed liner around the exterior base for maximum durability.

The entire install can usually be completed with basic tools in 1-2 days. Taking it slow and getting an extra set of hands will make the job much easier. Always follow the manufacturer’s specific installation instructions.

8. What kind of warranty and support does the manufacturer provide?

When buying a light duty cabin, it’s important to understand the warranty coverage and support services offered by the manufacturer:

- Length of coverage – Standard warranties range from 2-10 years against defects and workmanship issues. Longer terms provide more peace of mind.

- Covered components – Comprehensive warranties protect against leaks, structural failures, material corrosion, hardware breakage, etc. Read the fine print.

- Exclusions – Damage from accidents, misuse, overloading, or modifications may void the warranty. Understand any exclusions.

- Claim process – The easier the claim and repair process, the better. Look for companies with responsive customer service.

- Transferable – Some warranties can be transferred to a subsequent owner if you sell the truck. This adds resale value.

- Service locations – Look for manufacturers with authorized service centers near you for easier repairs and reduced downtime.

- Customer reviews – Check online customer reviews and forums to learn about real-world warranty experiences with different manufacturers.

- Customer service – How responsive is the company’s customer service? Do they have a track record of standing behind their products?

- Repair costs – Will you have to pay out of pocket for shipping or labor charges during warranty repairs? Get all costs covered.

- Registration – You must register the warranty within a specified time period after purchase to be covered. Don’t skip this step!

Understanding the warranty and having a point of contact for issues can give you confidence in your purchase. Paying a little more upfront for better coverage and manufacturer support is often worth it in the long run.

9. How do light duty cabins compare to fiberglass caps and camper shells?

Light duty cabins, fiberglass caps, and camper shells all provide an enclosed cargo space for pickup trucks, but have some key differences:

- Durability – Cabins are made of aluminum or steel which is more dent, rust, and impact resistant than fiberglass caps. Cabins are built for demanding work use.

- Security – Cabins have more robust door locks and mounting systems to keep cargo secure. Fiberglass caps can be pried off more easily.

- Weather protection – Cabins are fully sealed against the elements. Some fiberglass caps may leak over time as seals wear out.

- Capacity – Cabins provide much more enclosed space, often double a standard fiberglass cap. Great for bulky cargo.

- Access – Cabins feature larger doors and lift gates for easier access. Caps typically only have a rear hatch.

- Customization – More interior storage options are available with cabins to organize cargo. Caps have minimal options.

- Cost – Light duty cabins are a premium product and cost considerably more than fiberglass caps or shells.

- Aerodynamics – Smooth fiberglass caps reduce drag slightly more than enclosed cabins. Provides a small fuel efficiency benefit.

For demanding work use and maximum security, light duty cabins are ideal, but they come at a higher cost. Fiberglass caps are cheaper but less robust.

10. Are light duty cabins safe and secure for hauling equipment and tools?

Yes, light duty cabins provide very safe and secure transportation of equipment, tools, and other cargo when properly installed and used:

- Heavy-duty doors – Cabins feature sturdy, tightly sealing doors with multi-point locking systems to prevent break-ins.

- Impact-resistant walls – Aluminum and steel construction is dent and penetration resistant to protect cargo.

- Secure mounting – Robust bolt-on tie-down brackets firmly attach the cabin to the truck bed without movement.

- Tamper-proof design – Doors and hatches have pry-proof edges and tamper-resistant fasteners.

- Locking storage – Interior drawers, cabinets, and other storage options can be locked for tool storage.

- Obscured contents – Solid metal construction prevents contents from being visible. Deters thieves.

- Ventilation – Cabins have vents so you can safely secure gas-powered equipment without fume buildup.

- Fire protection – Metal cabins contain and isolate fire risks from flammable cargo better than fiberglass.

- Crash safety – Cabins are designed to secure cargo in the event of an accident to prevent load shift injuries.

Always properly tie down and restrain cargo inside the cabin and drive cautiously. Light duty cabins give you very good protection for your cargo with proper use.

Key Takeaways:

- Light duty cabins provide expanded, weatherproof cargo capacity and better organization.

- Match the cabin size to your truck bed length and payload capacity for optimal fit.

- Durable aluminum and steel construction offers better security than fiberglass caps.

- Interior storage and racks can be customized to suit specific cargo needs.

- Installation is doable with proper truck bed prep and mounting procedures.

- Carefully compare warranties from different manufacturers.

- Cabins are more expensive but much more robust and secure than fiberglass caps.

- Proper installation and restraint of cargo makes light duty cabins very safe for hauling.

Conclusion:

- Light duty truck cabins are an excellent solution for securely transporting equipment, tools, and other cargo.

- Their durable metal construction and customizable storage make them ideal for work, cargo, and commercial transport needs. By selecting the proper size and features, and taking care during installation, light duty cabins can provide many years of enhanced truck utility.

- While more expensive than fiberglass caps or shells, their superior security, protection from elements, and storage organization make them a valuable investment for the right truck owner. They allow you to get the most out of your pickup.

Kontraktor Rumah Kabin

Rumah Kabin Murah

Rumah Kontena Vs Rumah Kabin

Rumah Kabin Pasang Siap

Senarai Harga Kabin di Malaysia

Heavy Duty Cabin

Light Duty Cabin