Blog

10 Questions About Guard House Cabin

10 Questions About Guard House Cabin

- What are the different types of guard house cabins?

- What size guard house cabin do I need?

- What features should I look for in a guard house cabin?

- How much does a prefabricated guard house cabin cost?

- What are the pros and cons of prefabricated vs site-built guard house cabins?

- How do I choose the right contractor to build my guard house cabin?

- What are the electrical and utility requirements for a guard house cabin?

- How can I customize the design of my guard house cabin?

- What permissions and approvals do I need to build a guard house cabin?

- How long does it take to construct a prefabricated guard house cabin?

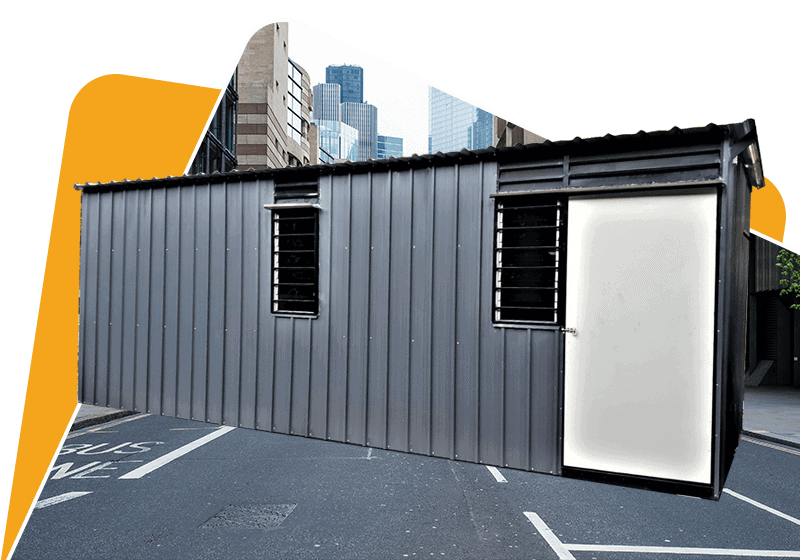

What are the different types of guard house cabins?

Guard house cabins, also known as security cabins or guard booths, provide shelter and workspace for security personnel at facility entrances. There are several types of guard house cabins to choose from based on your specific needs and budget.Prefabricated Guard House CabinsPrefabricated guard houses are pre-engineered cabins that are manufactured offsite and delivered ready for quick installation. They come in standard sizes and layouts that can be customized with options like windows, doors, electrical wiring and HVAC.

- Advantages: Quick to install, lower cost, customizable features, durable and low maintenance.

- Disadvantages: Limited customization of size and layout.

Common prefab guard house sizes:

- 8×8 ft

- 8×10 ft

- 8×12 ft

- 10×10 ft

- 10×12 ft

Modular Guard House CabinsModular guard houses are constructed using repeatable modular units that are manufactured offsite and assembled onsite. They provide more flexibility in size and layout compared to prefabricated units.

- Advantages: More customizable, flexible sizing.

- Disadvantages: Higher cost, longer installation time.

Custom Designed Guard HousesCustom designed guard houses are built completely onsite to your unique specifications. This allows for maximum customization but is the most expensive and time-consuming option.

- Advantages: Fully customized design and features.

- Disadvantages: Highest cost, longer construction timeline.

When choosing a type of guard house, consider your budget, needed features, timeline and customization requirements. Prefabricated units provide the fastest and most affordable option, while custom-designed cabins offer the highest level of personalization.

What size guard house cabin do I need?

Determining the right size for your guard house cabin depends on several factors:Number of occupantsConsider the maximum number of security personnel that need to be accommodated at one time. Most standard cabins accommodate 1-2 people comfortably.Workspace requirementsFactor in the amount of workspace needed for equipment like computers, radios, file cabinets etc. This will determine the minimum square footage required.Traffic volumeHigh traffic facilities may need larger cabins to manage visitor flow. Larger units in the range of 10×12 ft or 12×16 ft work better for busy entrances.Shift changesIf there are frequent guard shift changes, choose a cabin size that allows for adequate space during shift transitions.AmenitiesGuard houses that include amenities like a restroom or kitchenette will require more space.WindowsThe number and size of windows will impact the wall space available for furnishings. Limit windows in smaller cabins.Customization optionsPrefabricated units under 10×10 ft offer limited customization. Larger units or modular designs provide more flexibility.Ideal guard house size by facility:

- Small office building – 8×10 ft

- Large office complex – 10×12 ft

- Warehouse/storage facility – 8×12 ft

- Manufacturing facility – 10×12+ ft

- Public venue – 12×16+ ft

Consider getting quotes for different sizes to find the ideal balance of cost and functionality. It’s better to err on the side of more spaciousness when sizing your guard house cabin.

What features should I look for in a guard house cabin?

When selecting a guard house cabin, there are several beneficial features to look for based on your facility’s needs:

Windows – Strategically placed windows allow for good visibility of the entry point while protecting occupants from direct sunlight and inclement weather. Look for tinted windows and placement that avoids eye-level glare.

HVAC – Heating and air conditioning systems provide climate control for guard house comfort in all seasons. Central air or several wall-mounted units may be needed for larger cabins.

Interior lighting – Sufficient interior lighting ensures guards can perform tasks and paperwork safely. LED lights provide bright, energy-efficient illumination.

Exterior lighting – Lighting outside the guard house entrance improves visibility for guards and visitors during nighttime hours. Wall-mounted lights should illuminate the area without glare.

Interior paneling – Insulated wall and ceiling panels made of vinyl, galvanized steel or other durable materials are easy to clean and maintain.

Reliable power – Guard cabins have high electrical needs for lighting, computers, communications gear and other equipment. Sufficient panel capacity and outlets are essential.

Ergonomic design – Look for interior layouts optimized for the guards’ workspace with strategic counter placement, seating, storage, etc.

Safety features – Bullet-resistant glass, security cameras, intercoms, and duress alarm systems help ensure guard safety.

Climate control – Air conditioning, heating, ventilation and humidity control promotes healthy indoor air quality for 8-12 hour shifts.

Prioritizing these key features results in a functional, comfortable guard house cabin suited for security needs.

How much does a prefabricated guard house cabin cost?

Prefabricated guard house cabins provide a cost-effective security solution compared to custom built units. Here is an overview of the typical pricing:

Small units (8×8 ft – 8×10 ft):

- Basic prefab unit: $4,500 – $7,000

- With HVAC system: $6,000 – $9,000

- With bullet-resistant glass: $7,500 – $12,000

What are the pros and cons of prefabricated vs site-built guard house cabins?

Prefabricated and site-built guard houses each have their advantages and disadvantages:Prefabricated Guard HousesPros:

- Lower upfront cost

- Faster installation – ready in days or weeks

- Easier permitting process

- Customizable options like windows, colors, etc.

- Manufactured offsite for consistent quality

- Can be relocated and reused

Cons:

- Limited customization of size and layout

- Generally smaller size options

- Can feel impersonal or cookie-cutter

Site-Built Guard HousesPros:

- Fully customized design and size

- Can blend seamlessly into existing architecture

- Built to suit exact specifications

- Perceived as higher quality construction

Cons:

- Higher upfront cost

- Lengthy construction timeline – months

- May require architectural plans and permits

- Quality depends on contractor skills

- Fixed to site, cannot relocate

Overall, prefabricated units offer faster installation and lower costs, while site-built cabins provide unlimited customization. Assess your budget, timeline and custom needs when deciding.

How do I choose the right contractor to build my guard house cabin?

Choosing the right contractor is key to getting a high-quality guard house cabin installed on time and on budget. Here are tips for selecting the best contractor:

Verify experience – Look for contractors thoroughly experienced in guard house construction. Ask to see photos of completed projects.

Check reputation – Read reviews and ask for client references to verify quality work and professionalism.

Compare pricing – Get bids from at least 3 contractors. Compare costs for materials, labor and timeline.

Inspect licensing – Confirm the contractor has valid licensing and insurance for your state.

Request a detailed proposal – The proposal should cover materials, costs, project timeline, warranty and permits.

Outline specifications – Provide the contractor detailed specifications for design, size, features, utilities, etc.

Check financial stability – Choose an established contractor that is financially stable. Newer contractors can carry more risk.

Get everything in writing – Have a written contract covering costs, timeline, work scope, warranties, and payment schedule.

Arrange site visits – Schedule regular site visits during the build to inspect progress and ask questions.

Taking the time to carefully select the right qualified contractor will pay off with a smooth construction process and high-quality finished guard house.

What are the electrical and utility requirements for a guard house cabin?

Installing the necessary electrical and utility connections is key for powering essential systems in your guard house cabin. Here are the main requirements:

Electrical service – Guard cabins need a dedicated electrical service and panel, typically 100-200 amps depending on the size. The electrical line can be overhead or underground.

Lighting circuits – Separate circuits for interior and exterior lighting are ideal. LED lights minimize energy usage. Have backup emergency lighting.

Outlets – Multiple general use and dedicated outlets located throughout the cabin are needed for charging equipment.

Heating and AC – A dedicated circuit is required for any HVAC system like wall units or central air.

Ventilation – Fans or ventilation systems may need dedicated circuits. Proper ventilation is a must.

Security systems – The guard house will require circuits for security cameras, intercom systems, alarm systems and any other security electronics.

Communication lines – Phone, ethernet and cable lines should be routed into the guard cabin as needed.

Water and sewer – If including restroom facilities, water supply and sewer lines must be connected.

Consult with electricians and contractors early in the design process to ensure sufficient power and utilities to the guard house. Permitting may be required.

How can I customize the design of my guard house cabin?

Guard houses allow for great flexibility when it comes to customizing the design. Here are some options to personalize your security cabin:

Size – Choose from standard sizes or work with a modular builder to create a fully custom footprint to suit your space.

Exterior materials – Select durable low-maintenance finishes like vinyl, stone, stucco or brick rather than basic siding.

Roof design – Incorporate gables, overhangs or other roof shapes and detailing instead of a basic flat roof.

Windows – Strategically place windows for visibility and aesthetics. Add shutters or decorative window frames.

Interior layout – Optimize the interior space with angled walls, half walls, counter shapes and built-in storage.

Interior finishes – Upgrade to higher-end flooring, wall paneling and cabinetry for a more custom feel.

Technology integrations – Flush mount monitors, touch screens and other tech seamlessly into the cabin design.

Furnishings – Choose customizable furniture pieces that maximize the available space.

Exterior lighting – Use accent lighting, lanterns and other fixtures to enhance the exterior.

Landscaping – Frame the cabin with plants, trees, fencing, rock walls or other landscaping features.

Taking advantage of these and other options will help your guard house cabin better match your facility’s look and security needs.

What permissions and approvals do I need to build a guard house cabin?

Constructing a new guard house cabin typically requires obtaining certain permits and approvals first:

Zoning permit – Most areas require a zoning permit to ensure the guard house complies with municipal land use codes for size, height, setbacks, and use.

Building permit – A building permit is needed to construct any new permanent structure. The application requires submission of detailed plans.

Electrical permit – An electrical permit must be obtained to run new electrical service and circuits to the guard cabin.

Planning commission approval – Some jurisdictions require planning commission review and approval, particularly for larger guard houses.

Architectural review – There may be an architectural review process to ensure the guard house design fits aesthetically into the surrounding buildings.

Security review – For facilities like government buildings, airports or laboratories, there may be a security review of the guard house design.

How long does it take to construct a prefabricated guard house cabin?

One of the major benefits of prefabricated guard houses is the quick construction time compared to site-built cabins. Here is an overview of typical timelines:

Production time:

- 2-4 weeks

The prefabricated components of the guard house are manufactured offsite during this timeframe. This includes the walls, roof, windows, electrical, etc.

Shipment time:

- 1 week

Once complete, the guard house components are loaded onto trucks for shipment to your location.

Foundation preparation:

- 1-2 weeks

While production is in progress, the site is prepared by grading, pouring a concrete slab, installing utilities, etc.

Assembly time:

- 1-3 days

When the prefab guard house arrives, a crew will assemble it quickly by joining the components.

Interior finish work:

- 1-2 weeks

The interior is finished off with flooring, fixtures, paint, and any customizations.

Inspections and approvals:

- 1-2 weeks

The local building department inspects the completed guard house and issues any certificates of occupancy.

Total timeline: 6-10 weeks

By having components built offsite in parallel, prefabricated guard houses can be installed in 1-2 months, far faster than custom construction.

Key Takeaways

- Guard houses come in prefabricated, modular and custom site-built types to suit needs.

- Standard sizes are 8×8 to 12×16 ft, based on traffic, shifts, and amenities.

- Key features include HVAC, ample lighting, bullet-resistant glass, and ergonomic layouts.

- Prefabricated cabins offer faster installation at a lower cost.

- Carefully vet and choose qualified contractors for the project.

- Electrical, lighting, and security systems require planning and permits.

- Custom designs allow personalized aesthetics and functionality.

- Permits and approvals are needed from zoning, building, and planning departments.

- Prefab guard houses can be installed in just 6-10 weeks.

Conclusion

In summary, carefully planning key factors like size, features, utilities, design, and permitting is crucial for constructing a high-quality, functional guard house cabin tailored to your facility’s security needs. Leveraging the benefits of prefabricated components can allow for faster installation without sacrificing customization. With upfront preparation and selection of experienced contractors, guard houses can provide shelter and workspace to help security personnel perform their duties effectively. The investment will pay dividends in enhanced access control and peace of mind.

Kontraktor Rumah Kabin

Rumah Kabin Murah

Rumah Kontena Vs Rumah Kabin

Rumah Kabin Pasang Siap

Senarai Harga Kabin di Malaysia

Heavy Duty Cabin

Light Duty Cabin