Blog

10 Popular Questions About Prefab Homes

10 Popular Questions About Prefab Homes

- What are the main advantages of prefab homes?

- How much cheaper are prefab homes compared to traditional construction?

- What customization options are available with prefabricated homes?

- How quickly can a prefabricated home be built?

- Are prefab homes lower quality than site-built homes?

- Can prefab homes be energy efficient and environmentally friendly?

- What foundation options exist for prefabricated homes?

- Can prefab homes be moved or expanded after initial construction?

- What sizes and floor plans are available with prefabricated homes?

- What are the best uses for prefabricated homes (residential, commercial, etc.)?

What are the main advantages of prefab homes?

Prefabricated, or prefab, homes offer many benefits compared to traditional stick-built construction. Here are some of the main advantages of choosing a prefab home:

- Faster construction time – Prefab homes are built in a factory in modules or panels, then transported to the site and assembled. This allows for faster completion, often in a matter of weeks or months rather than months or years for site-built homes.

- Lower costs – Factory construction with assembly line techniques can reduce labor and material costs by up to 20% compared to traditional building. Prefab allows for mass production efficiencies.

- High quality – Prefab factories allow for greater oversight and quality control measures compared to individual on-site construction. The controlled environment reduces the potential for errors.

- Customization – Many prefab companies offer custom floor plans and the ability to choose finishes. Customization allows you to get the home layout and look you want.

- Eco-friendly – Prefab homes are designed for energy efficiency. High performance insulation, windows, and HVAC systems can be installed more precisely in a factory. Many prefab homes are built solar-ready.

- Flexible – Prefab homes can be configured for different lots and sites with modifications to the foundation and certain components. They can also be expanded with add-on modules.

- Durable – Factory built components are protected from weather during construction. Materials like steel framing provide enhanced structural integrity and resistance to rot, mold, and pests.

In summary, prefabricated homes offer faster, cheaper, higher quality construction with customization flexibility and green building benefits. The controlled setting alleviates many issues that affect on-site building.

How much cheaper are prefab homes compared to traditional construction?

Prefabricated homes, on average, cost between 10-20% less compared to traditional stick-built homes, owing primarily to:

- Lower labor costs – Factory construction requires less on-site labor. Assembly line techniques improve efficiency. Overall lower labor costs.

- Bulk material discounts – Building materials are purchased in bulk for the whole factory vs per custom home. Prefab companies get discounts.

- Reduced waste – Materials are precisely cut by computer modeling. Much less wasted material than stick-built job sites.

- Faster construction – Shorter build time equates to less financing costs and overhead for buyers.

- Standardized plans – Homes use optimized designs. No need to reinvent/engineer the wheel with each custom home.

While prefab homes are cheaper overall, the exact cost difference depends on factors like:

- Location

- Foundation type

- House size

- Layout complexity

- Finishes and fixtures

- Degree of customization

- Manufacturer

For example, a 1,500 sq ft prefab home may cost $140 per sq ft compared to $160 per sq ft for the same size site-built home. That’s a savings of $30,000. Cost savings are in the structure – not necessarily finishes. Upgrades close the gap.In the end, prefab offers compelling value. You still get quality construction with custom looks. And as techniques improve, prefab cost savings will likely grow over time.

What customization options are available with prefabricated homes?

While prefab construction uses standardized components, there are still abundant ways to customize your prefabricated home:

- Floor plan options – Most companies offer multiple floor plans or the ability to fully customize plans. Open concept, multi-story, and unique layouts are possible.

- Exterior finishes – Choose exterior siding materials and colors. Options like brick, stone, stucco, and metal can mimic any architectural style.

- Interior finishes – Select interior wall colors, flooring, cabinets, countertops and other finishes. Higher end options like granite are available.

- Fixtures and appliances – Pick standard or upgrade options for lighting, plumbing fixtures, appliances, entertainment systems, and more.

- Roofing – Choose asphalt, metal, slate, cedar shake, or even solar roof tiles. Roof pitch and gables can be configured.

- Windows – Select window sizes, placements, and styles to fit your aesthetic vision. Energy efficient models available.

- Landscaping – Work with your contractor to modify grading and drainage and install plants, trees, fencing, and hardscapes.

- Add-ons – Many companies offer add-on modules like garages, porches, additional rooms and entire guest homes.

While prefab uses standard components, there are abundant ways to make your home unique with upgrades and additions. Aesthetically, most prefab homes are indistinguishable from site-built homes.

How quickly can a prefabricated home be built?

One of the biggest advantages of prefabricated home construction is the speed from start to finish. Here is an overview of typical prefab home construction timelines:

- Factory construction – The home itself can be finished in the factory in 4-12 weeks depending on size and customizations. Multiple homes can be built concurrently.

- Site preparation – The site is prepared with utilities, foundation, and access in 2-6 weeks prior to delivery. Permits are secured.

- Delivery – The finished modules are transported to the site by truck over 1-3 days depending on distance.

- Assembly – A crew assembles the home on site typically in 2-5 days by craning modules and bolting together.

- Finish work – Interior finishes, fixtures, utilities hookups are completed over 2-6 weeks depending on extent.

Total timeline – From contract signing to move-in ready is typically 12-24 weeks, subject to factory capacity, permitting, and site prep. Comparatively, traditional stick-built homes often take 6-12 months to complete because construction happens sequentially on-site. Delays from weather, contractors, or materials can further lengthen the process.Prefab factory construction happens concurrently in a controlled environment. The on-site work is limited to assembly, reducing delays. So while a custom home can drag on, prefab delivers a high quality home remarkably fast.For buyers needing a home right away or wanting to minimize construction loans, prefab represents the fastest path to get settled. The accelerated timeline is one of the biggest perks of factory-based construction.

Are prefab homes lower quality than site-built homes?

Prefab homes used to have a reputation for lower quality, but modern techniques mean they can meet or exceed the quality of site-built homes:

- Precise construction – Factory conditions allow for tighter precision and less margin of error compared to individual on-site building.

- Qualified workers – Factory employees are trained and experienced working specifically on prefab home assembly. More consistent workmanship.

- Quality materials – Prefab manufacturers build relationships with suppliers to procure quality graded and durable construction materials.

- Strict tolerances – Components are engineered and manufactured to tight tolerances that limit sagging, warping, and other issues over time.

- Consistent insulation – Insulation and vapor barriers are installed uniformly in a factory vs reliance on on-site labor. Better energy efficiency.

- Controlled conditions – Factory conditions eliminate weather-related construction delays that can compromise quality.

- Automated processes – Automated equipment like computer-controlled saws ensure precision cuts, reducing waste and errors.

- Rigorous testing – Structural integrity, energy efficiency, and safety are tested in controlled labs to meet or exceed building codes.

- Warranties – Most prefab companies offer comprehensive warranties on both structure and finishes, ensuring quality and fixing issues.

In summary, prefabrication technology has improved tremendously. When built by reputable companies, prefab homes match or surpass quality compared to site-built homes.

Can prefab homes be energy efficient and environmentally friendly?

Absolutely. Prefabricated homes offer great flexibility to incorporate green building and energy efficiency features:

- Optimized insulation – Factory installed insulation uniformly envelops the home without gaps that compromise efficiency.

- High performance windows – Energy efficient windows come standard. Strategic placements optimize solar gain during colder months.

- Efficient HVAC – With precise home dimensions, HVAC systems can be engineered and installed for maximum efficiency.

- Solar ready – Prefab homes are designed to seamlessly integrate solar systems. Roof designed for solar panel load.

- Sustainable materials – Many prefab companies utilize recycled, non-toxic materials along with responsibly sourced lumber.

- Smart home tech – Home automation systems to control lighting, HVAC, appliances can be factory installed.

- Net zero options – Upgrades like solar, geothermal, battery storage, rainwater harvesting allow homes to produce as much energy as they use.

- Passive house – Super insulated prefab envelopes can meet rigorous Passive House energy standards.

- LEED certified – Prefab allows green certification through the LEED (Leadership in Energy and Environmental Design) program.

With smart design and conscientious materials selection, prefab homes can minimize environmental impact and energy costs. Prefab’s precision lends itself well to green building.

What foundation options exist for prefabricated homes?

Prefabricated homes offer flexible foundation options to accommodate different sites, budgets and performance needs:

- Concrete slab – A poured concrete foundation. Good for flat sites. Offers stability and energy efficiency.

- Stem wall – Concrete walls with compacted gravel base. Most affordable foundation option.

- Basement – A full or partial poured concrete basement. Allows for extra living space.

- Crawl space – A shallow foundation with pier footings. Allows for plumbing and HVAC access.

- Piers – Concrete piers driven into the ground. Used for sites with expansive or poor soils.

- Piles – Steel piles driven deep into the earth. Used for unstable, steep terrain or flood zones.

- Wood foundation – Treated wood foundation walls on concrete footings. Offers insulation benefits.

- Mobile home foundation – Designed for manufactured homes. Usually includes anchor tie-downs.

The optimal foundation depends on the site, climate, and budget. Many prefab companies have engineers to customize the foundation design for local conditions. Foundations can even be re-used if the home is relocated.

Can prefab homes be moved or expanded after initial construction?

One advantage of prefabricated construction is that it can be moved and expanded:Moving the home

- Homes are structurally designed to be relocated. The structure is strengthened.

- The home is detached from the foundation and utilities, put on wheels, and towed to a new site.

- Works best for smaller homes built on pier, pile, or crawl space foundations.

- Makes it easy to take a home with you to a new property.

Expanding the home

- Additional modules can be added on to increase living space. New bedroom or bathroom pods are common.

- Plumbing, electric and HVAC are designed to link up to new additions.

- Multi-story models allow building up. New second floors can be added.

- Expansions need permits and foundation adaptations, but are more feasible than with site-built.

While not always simple, prefab homes offer more flexibility than conventional construction. The ability to move or expand your home is a unique advantage of the modular approach.

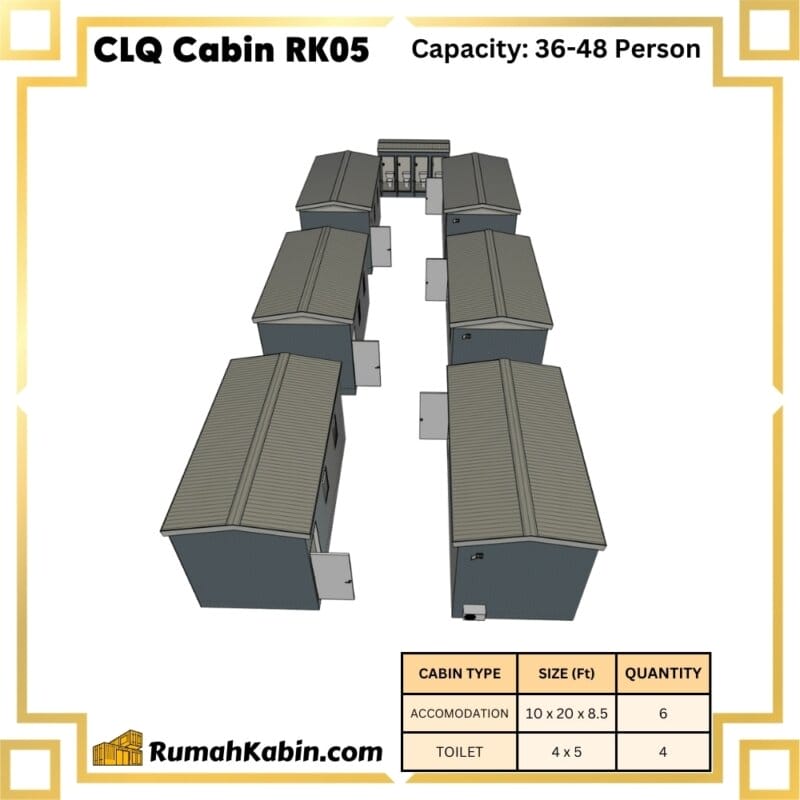

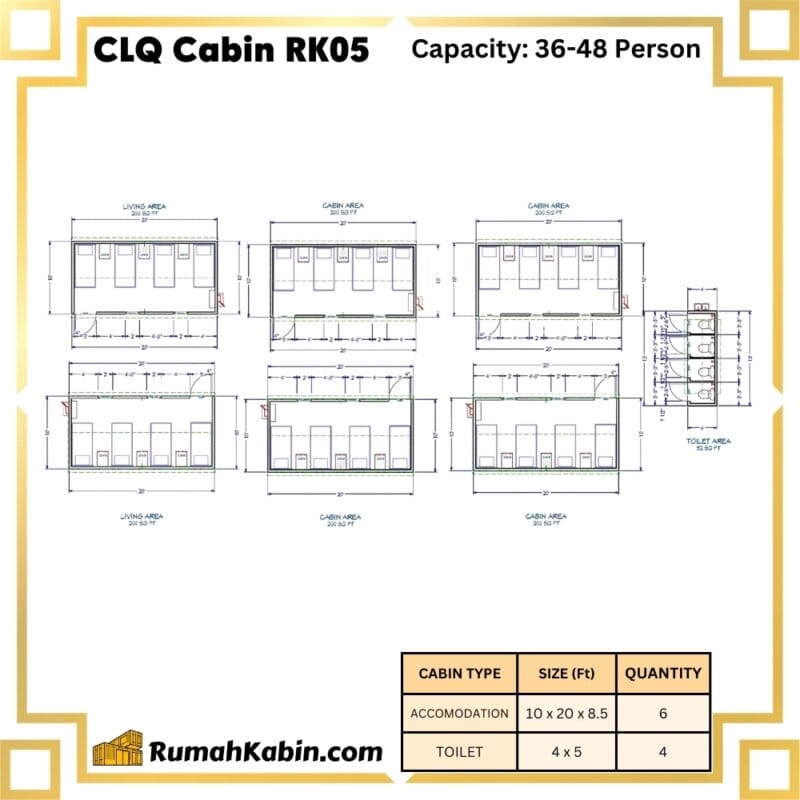

What sizes and floor plans are available with prefabricated homes?

Prefab homes come in a full range of sizes with customizable floor plans: Sizes

- Tiny prefab homes – 500 sq ft or less

- Small prefab homes – 500 – 1000 sq ft

- Medium prefab homes – 1000 – 2500 sq ft

- Large prefab homes – 2500 – 4000+ sq ft

Floor plan options

- One story

- Two story

- Open concept

- 1-4+ bedrooms

- 1-3+ bathrooms

- Kitchen, dining, living combos

- Bonus rooms, dens, lofts

- Attached garages

Customization

- Modify standard plans or fully customize

- Add/remove walls, doors, windows

- Unique architectural elements

- Flexible room sizes and layouts

Prefab homes come in all shapes and sizes to suit any lifestyle. The manufacturing approach allows for great flexibility compared to site-built construction. Homes can be configured as:

- Compact 1-2 bedroom starter homes

- Spacious 4+ bedroom family homes

- Luxury custom homes with high end finishes

- Vacation properties and guest houses

- Urban infill on small lots

- Rural properties with acreage

With an extensive catalog of floor plans and the ability to fully customize layouts, prefab homeowners can get the perfect home tailored to their needs. Multi-module designs also allow for future expansion capabilities.

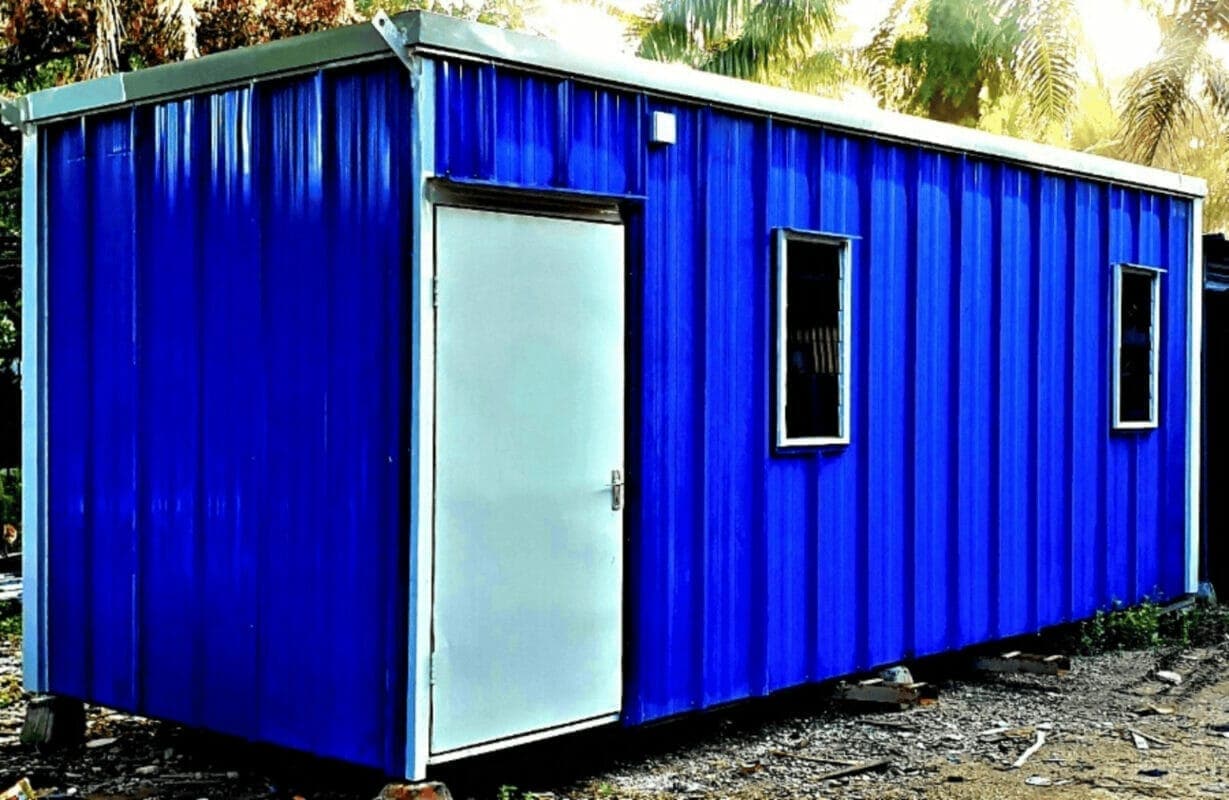

What are the best uses for prefabricated homes (residential, commercial, etc.)?

Prefabricated homes offer advantages across many building applications:Residential

- Primary single family homes

- Vacation homes and cabins

- Rental properties and apartments

- Affordable and workforce housing

- Disaster relief and emergency housing

- Tiny homes and accessory dwelling units

Commercial

- Small offices and retail spaces

- Restaurant and food service buildings

- Event venues and temporary structures

- Classrooms and portable buildings

- Medical clinics and dental offices

Other uses

- Guest houses and pool houses

- Home additions and expansions

- Garages, workshops, and sheds

- Hunting and fishing cabins

- Backyard studios and offices

Prefab’s flexibility, speed, and cost effectiveness make it suitable for any building need. Homes and commercial buildings can be configured with high quality finishes indistinguishable from site-built construction. The reduced disruption and ability to pre-outfit spaces make prefab ideal for many applications.

Key Takeaways

- Prefab homes are built faster in factories and assembled on site, reducing construction timelines.

- Factory construction and bulk material purchases result in prefab homes costing 10-20% less compared to site-built homes.

- Numerous customization options from layouts to finishes allow for unique looks and floor plans.

- Quality of prefabricated homes equals or exceeds site-built homes thanks to manufacturing precision and quality control.

- Green energy features like solar, tight insulation, and efficient HVAC can be incorporated seamlessly.

- Different foundation types can be used to accommodate sites and relocation or expansion possibilities.

- Prefab homes come in all sizes with completely customizable floor plan options.

- Ideal uses span residential, commercial, hospitality, offices, and more.

Conclusion

In summary, prefabricated homes offer faster, cheaper construction with quality and customization rivaling traditional building. Technological advancements and manufacturing efficiencies make prefab homes an ideal choice for many applications from single family homes to commercial spaces. With benefits like flexibility, sustainability, and resilience, prefab represents the future of construction.